News

How to Successfully Implement a KANBAN

23/05/2025

In this article, we will describe the experience of introducing Kanban in a company that was increasing its production volumes while simultaneously implementing a new ERP system.

Introducing a Kanban system in a company transitioning from a craft-based operation to an industrial one is a complex yet highly strategic challenge. It offers the opportunity to simplify and avoid the escalation of supply chain management complexity across hundreds of part numbers. The main goal of the project was to move from a Push management system, typical of many subcontracting businesses, to a leaner, more visual approach, where materials could be managed more efficiently, without overloading the ERP system and without requiring constant stock checks by the planning office.

Material management within the company was primarily handled through two conventional methods, both reliant on ERP system functionality:

1. Material Requirements Planning (MRP): The system calculated requirements based on customer orders and bill of materials (BOM) explosions, generating production or purchase orders. However, this approach failed to aggregate the demand for identical components across different part numbers, leading to multiple, often duplicated, orders each month for semi-finished items used in different finished products.

2. Fixed Reorder Point: When stock levels dropped below a predefined threshold, the system generated a new order to restore inventory to optimal levels. This method also had limitations: it didn’t provide a visual management tool and could lead to delays or stock overloads, particularly when withdrawals or deliveries were inaccurate or incorrectly recorded in the ERP system, resulting in erroneous inventory data.

Both methods proved inadequate for a production system that required greater responsiveness and operational simplicity. The objective, therefore, was to introduce a more dynamic and flexible system that ensured material availability without continuous checks on inventory levels, withdrawals, and restocking.

STARTING POINT FOR IMPLEMENTING A KANBAN SYSTEM: COMPONENTS AND BOM ANALYSIS

One of the first challenges identified was managing components shared across multiple products. Often, identical materials were assigned different part numbers because they were linked to finished products rather than to a standard semi-finished code.

The first step was to harmonise the codes of all those components that, despite having different BOM codes, were physically identical. This allowed the company to:

- Aggregate demand for the same semi-finished component across multiple products

- Avoid fragmented micro-productions that led to inefficient use of production resources

- Improve visibility of aggregated consumption, thereby easing the transition to Kanban.

Once the codes were standardised, the average consumption of each component was estimated using delivery schedules and historical production data. This made it possible to identify which materials could be produced or purchased in stock, those with repeatable or significant monthly usage and low production or procurement costs, thus improving availability without causing excessive capital tie-up.

Selecting Materials for Kanban Management

Not all components were suitable for make-to-stock management. Specific criteria were therefore applied to identify which materials should be included in the Kanban system:

- Small size and low value: These could be produced in advance and stored without occupying too much space or tying up excessive capital.

- High turnover and consistent consumption: Frequently used materials with predictable usage patterns, for which Kanban ensured smooth and uninterrupted replenishment.

- Bulky or high-cost materials were managed using traditional MRP-based logic to avoid overstocking.

Implementing the Kanban System

Once the components to be managed via Kanban had been selected, the system was structured according to the following steps:

1. Defining the Role of Internal Logistics

A logistics flow Manager was appointed to handle the physical management of Kanban cards. This role included monitoring stock and available containers, and transferring Kanban cards to planners as a signal that replenishment was required.

2. Calculating the Kanban Stock Level

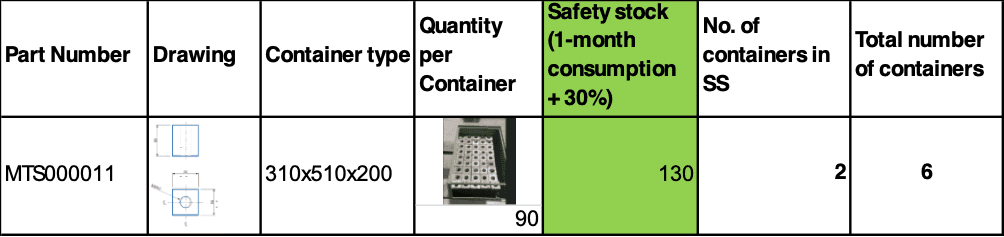

For each Kanban code, average monthly consumption was estimated, production lead time (i.e. the time between order launch and component availability) was calculated, and the required stock level to cover consumption during the lead time was defined, with an additional safety buffer.

A three-tier stock rule was then applied:

- Red cards: Safety stock (1/3 of total stock).

- Yellow cards: Operating stock (2/3 of total stock).

- Green cards: Available stock with no immediate need for reordering.

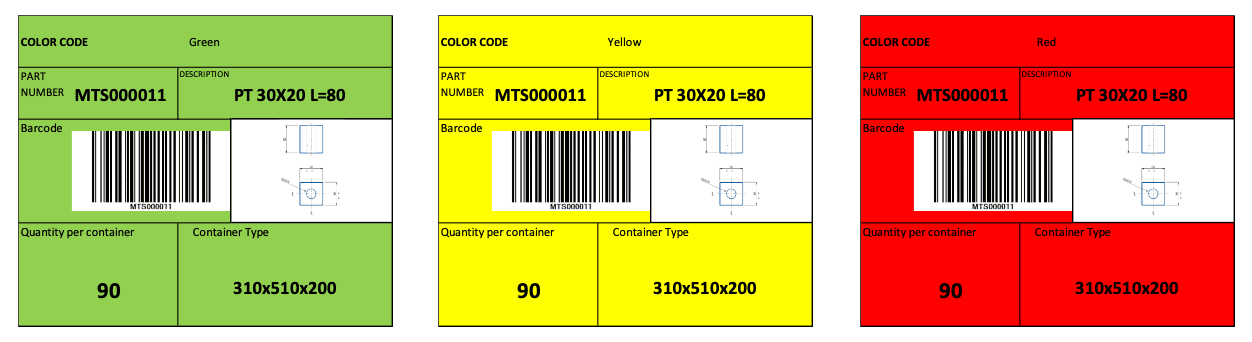

3. Creating and Managing Kanban Cards

Physical Kanban cards were created for each component, including the component code and image, quantity per container, production department to launch the order, delivery point, and card colour indicating stock level.

Fig. 1 – Example of Kanban quantity calculation scheme

Fig. 2 – Colour-coded cards to set replenishment priorities

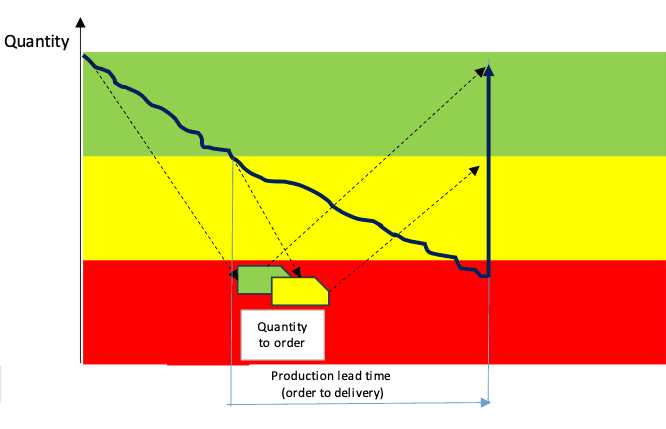

Each time a container was withdrawn from the warehouse, its card was moved to the collection rack. When a yellow card was collected, a production order was launched to replenish the material. At regular intervals (once per shift), the logistics operator monitored the Kanban card racks—one pocket per code. If yellow cards were present, all cards for that code were sent to Production Planning to launch a work order equal to the total quantity of those cards. The cards were then returned to the boxes awaiting processing.

Fig. 3 – Reorder flow based on card colour

RESULTS

After a few weeks of testing and fine-tuning, the Kanban system delivered significant improvements:

- Reduced stockouts, thanks to automatic replenishment based on actual consumption.

- Improved visibility of material flows, with no need for constant inventory checks by the planning office.

- Lower management complexity, with an intuitive colour-based system.

- Optimised production and purchase orders, reducing micro-orders and waste.

- Increased engagement of shop-floor operators, who now had direct control over stock without waiting for instructions from Production Planning.

The introduction of Kanban transformed the way high-turnover, low-value materials were managed, making the process leaner, more transparent, and more responsive. The system was well received by both Production and Logistics teams due to its simplicity, demonstrating that process improvement doesn’t always require complex IT solutions, but can also be achieved through visual, immediate tools.

Creating and Managing a Kanban System Requires Robust Lean Expertise. Advance School’s training programmes transfer state-of-the-art Lean knowledge at Green Belt, Black Belt, and Champion levels, and prepare participants for international certifications from IIBLC®, the International Independent Board for Lean Certification. For more information or to register, please contact Jessica Mariotti: info@advanceschool.ch

Courses linked

-

Master Green Belt in Lean – CGBL – 1st Level

Executive Master designed to prepare the participant to the international certification Certified Green Belt in Lean (CGBL) of IIBLC®, International Independent Board for Lean Certification. » -

Master Green Belt in Lean - CGBL - 1st Level - Interactive Live Webinar

Executive Master in Live Webinar mode, that prepares the candidates for the international certification Certified Green Belt in Lean (CGBL) of IIBLC®, International Independent Board for Lean Certification. » -

Master Black Belt in Lean - CBBL - 2nd Level - Interactive Live Webinar

Executive Master in Live Webinar mode, that prepares candidates for the international certification Certified Black Belt in Lean (CBBL) of IIBLC® , International Independent Board for Lean Certification. » -

Course Yellow Belt in Lean - IIBLC® endorsement

The aim of the programme is to create a basic level of knowledge about Lean for the professional, as well as for an organization that wishes to begin a project of change or to make one sustainable. The exam is in english and endorsed by IIBLC®, International Independent Board for Lean Certification. » -

Master Champion in Lean - CChL - 3rd Level

Executive Master designed to prepare candidates for the international certification Certified Champion in Lean (CChL) of IIBLC®, International Independent Board for Lean Certification. »