Participation fees vary depending on when you subscribe. Don’t miss our offers!

Master Green Belt in Lean – CGBL – 1st Level

Testimonials

See all >

DURATION

5 days in 3 months

UPCOMING COURSES

18 March 2026 Basel

26 March 2026 Lausanne

PRICING

3820 CHF + VAT (includes exam)

The course is delivered in 5 training days and ends with the discussion of a simulated exam. After the course, the participant will take the final exam for the CGBL certification, Certified Green Belt in Lean issued by IIBLC® - International Independent Board for Lean Certification (www.iiblc.org).

The aim of the course is to provide the tools to become member of an improvement team, learning the following basic concepts and Lean techniques:

• Transfer the Lean vision of how to create value for the customer

• Provide specific knowledge in the Lean area, the techniques and tools to be used to identify the flow of value and identify sources of waste

• Provide a structured approach to follow for a successful Lean implementation that also describes the cultural and organizational changes needed

• Through Case Study of Lean implementation, explain the critical issues to be addressed and the solutions adopted, accelerating the learning process

• Prepare to pass the Lean Green Belt (CGBL) IIBLC® exam

The course is delivered by IIBLC® certified instructors, with many years of teaching and professional experience in the Lean area.

Advance also offers in-house training programmes on request.

"I am very pleased with the Interactive Lean Green Belt course at Advance School that has allowed me to learn Lean Best Practices, and to become internationally certified. Between the classroom sessions and the Interactive Learning format, I chose the latter for work reasons, and also because I already had experience in Lean: I found the course very well structured and up-to-date, and the instructors were extremely well prepared". Luca Borgatti, Plant Manager, Cargill Starch & Sweeteners, Italy.

-

Teaching plan

READ THE DETAILS ▾

MASTER STRUCTURE

The course includes:

- a classroom training phase

- an individual study phase with remote support from instructors

- a simulation of the classroom exam with discussion of the results

Practical exercises are conducted during the course to allow immediate verification and application of the concepts outlined in the classroom, and use the tools adopted in Lean implementations to identify Value flows and waste sources. Successful Lean implementation Case Studies are also discussed.

The course is structured across 5 days of classroom training with certified instructors.

Teaching is in English.

DETAILED PROGRAMME

1. Introduction to Lean

What is Lean

History

Business Strategy

Ford, GM and Toyota system

The House of Toyota

The 5 Lean principles: Value, Value Stream, Create Flow, Pull, Perfection

2. Lean Principles

2.1 Defining Value and Waste

Value added activities: Definition and Recognition

Viewpoint of the Customer

Muda/Mura/Muri

7 Muda (7+1): Definition and Recognition

Lead Time: Components of Lead Time

Effects of shorter Lead Time

2.2. Identifying the Value Stream

Basic principles of Value Stream Mapping

Defining product families

Current state Value Stream Map

Basic symbology

Process box - Boundaries

Data box

Inventory triangle (production, office, service)

Material flow

Production Planning

Transportation

Kanban loops and supermarkets

Inventory, Waiting and Delay

Information flow

Lead Time ladder: Components, Meaning

Cycle Time

Process Time

Single Stream VSM: How to start drawing, Paper & Pencil drawing, Software based VSM

Future state Value Stream Map

Loops and Symbology

2.3 Creating Flow

Takt Time: Definition and Calculation

Continuous flow vs. Job Shop

One-Piece-Flow

FIFO lanes

5S technique

SMED technique

• Definition of a setup

• Why (EPEI, Flexibility, Capacity, Cost reduction)

• Internal vs. external setup

• Converting internal to external setup

• Setup instructions

2.4 Pull from Customer demand

Pacemaker

Interval: Definition and Calculation

EPEI

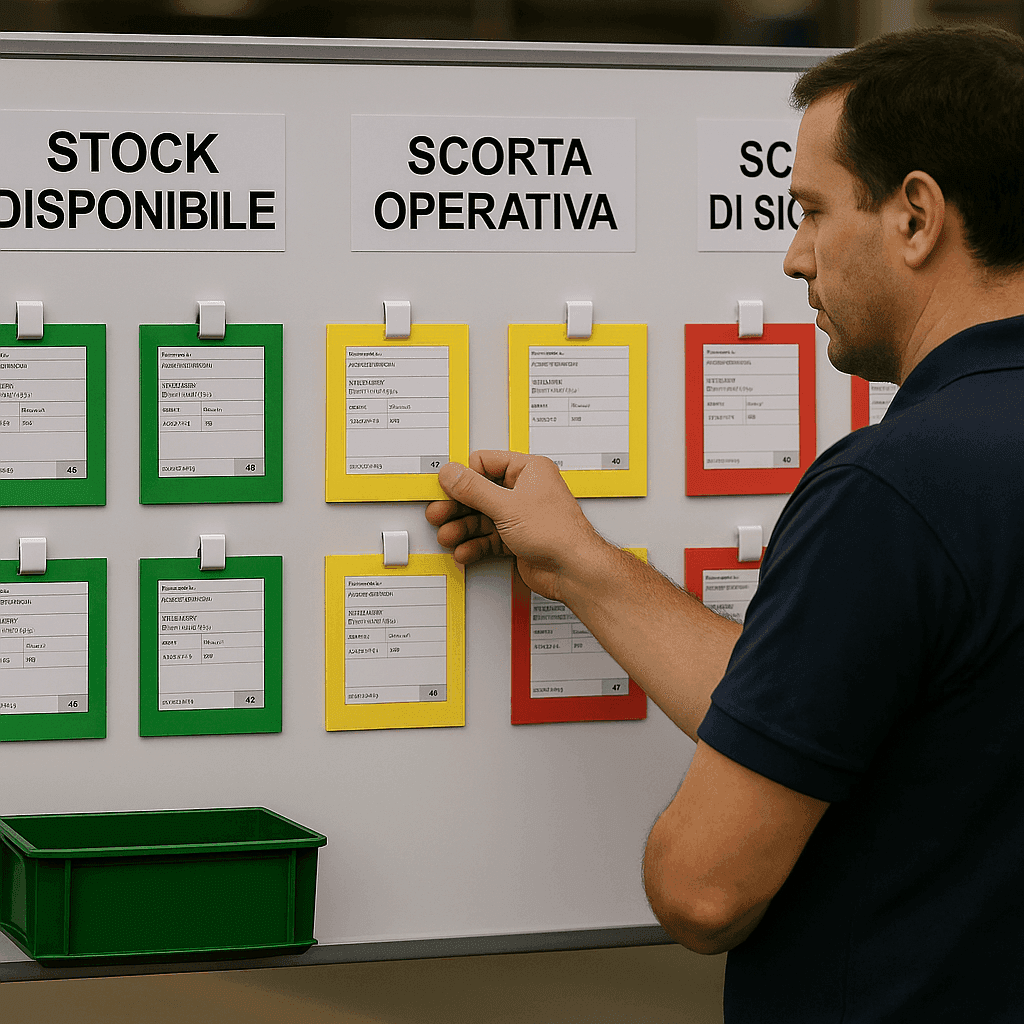

Kanban definition

Kanban types

• Supermarket

• Withdrawal Kanban

• Production Kanban

• Specific Kanban

• Generic Kanban

• Two (three)-bin system

Kanban and ERP system

Heijunka

2.5 Striving for Perfection

Kaizen

Kaizen-event

Standardised work: Definition, Importance, Work instructions, Continuous improvement

Poka-yoke

Visual Management

• Power of visual control

• Andon

• Marking, spaces, pictograms

• Daily reporting board

• Weekly reporting board

• Management reporting

Basic Lean measures

• Throughput time

• WIP

• Scrap/rework/PPM

3. Improvement Management

3.1 Basics of Project Management

Introduction to Project Management

Triple Constraint Management

Five Process Groups of Projects

Nine PMI Knowledge Areas

Project Management Tools

• Project Charter

• Work Breakdown Structure (WBS)

• Schedule development

• Cost estimating

• Responsibility Assignment Matrix (RAM)

• Risk Management

• Progress reporting

3.2 Complementary Improvement Methodologies

Six Sigma

• Jidoka

• Complexity – Variation – Mistakes

• DMAIC improvement methodology

• Basic Six Sigma Tools

TQM tools

• PDCA

• Pareto

• Ishikawa

• Flowchart

• Histogram

• Check sheets

• Scatter diagram

• Control sheets

• Five Why’s

Process Mapping

-

Who is the course aimed at

READ THE DETAILS ▾

- Representatives and staff in the areas of Production, Supply Chain, Quality, Purchasing and Organisation in the Industrial and Services sectors;

- Area Operations Consultants;

- Plant Managers;

- Production and Process Engineers;

- Companies wishing to implement Lean

-

EXAMS

READ THE DETAILS ▾

The exam is a multiple-choice test with 80 theoretical questions (paper & pencil format) in English. The candidate has 3 hours to complete the exam. A score of 70% is required to pass the exam.

EXAM DATE

DEADLINE15/03/2025

14/02/2025EXAM DATE

DEADLINE14/06/2025

16/05/2025EXAM DATE

DEADLINE20/09/2025

22/08/2025EXAM DATE

DEADLINE13/12/2025

14/11/2025REQUIREMENTS There are no pre-requirements. LOCATION Basel

On request, the exam can be taken in-house at the Company’s offices.REGISTRATION Send the registration's request to: info@advanceschool.ch

Within 10 days before the exam, a confirmation email will be sent by Advance which will indicate the time, the address and all the details.

-

Pricing and enrolment

READ THE DETAILS ▾

ENROLMENT FEE

3870 CHF + VAT

For registrations received 45 days before the start date of the course, it is foreseen a 5% rebate on the enrolment fee.

Note: The fee includes both teaching material and registration for the exam.

The course requires a minimum of 6 participants for the activation. Seats are limited in order to allow optimal interaction between participants and instructors.

To enrol, send the registration form with the receipt of the bank transfer or a purchase order to the following Email: info@advanceschool.ch

INSIGHTS

Linked News

-

22/02/2025

Employee Engagement in Lean Management: A Key Driver of Value Creation

Read how active employee engagement is at the core of lean management success. It discusses the vital role of empowering employees and the dynamic interplay between leadership and team members, using examples from companies like Toyota, Nike, and GE to illustrate how innovation, waste reduction, and continuous improvement are achieved. » -

27/03/2025

Leveraging Industry 4.0 to Enhance Value Creation in Lean Management

Discover how the timeless principles of Lean—efficiency, waste reduction, and continuous improvement—are being supercharged by cutting-edge technologies like AI, IoT, and Big Data. From smart factories to predictive maintenance, this powerful synergy is redefining operational excellence and setting a new standard for agile, data-driven value creation. » -

23/05/2025

How to Successfully Implement a KANBAN

This article outlines the successful implementation of a KANBAN system in a company. It details the transition from traditional MRP and reorder point methods to a lean, visual approach that improved material flow, reduced stockouts, and simplified operations. Through real-world steps—component standardization, Kanban card setup, and logistics coordination—the company achieved a more responsive and efficient supply chain without relying on complex IT systems. » -

02/02/2026

Advance launches a new Lean Yellow Belt online course

The Lean Yellow Belt online course, entirely designed and developed by our school, is based on the best practices of the International Independent Board for Lean Certification. »