2021

New Lean Implementation: Lean Methodology's 5S

23/06/2021

Implementation of the Lean approach in the workplace: the power of the 5S

The consultancy activities of the Advance SC Solutions team continue.

One of our clients - a multinational producer of hydraulic valves - had to review its company processes following a period of extremely strong growth in production volumes, low stocks and difficulty procuring raw materials.

The goal of the company was to increase the productivity of the mechanical processing and assembly divisions, at the same time also improving the efficiency of the divisions and material flows, and to this end it chose Advance for a programme of consultancy and on the job training.

The aim of the Management was to identify an effective work method that didn’t interfere with production rhythms.

The requirements were therefore as follows:

- Increase in productivity

- Increase in efficiency

- Streamlining of processes and flows in the divisions

The first step was to identify the tool that best fitted the needs of the customer.

Advance’s aim was to adopt a tool that was easy to implement and understand, and also capable of quickly and easily solving smaller problems. At the same time it also had to be accessible by all with the direct involvement of the workforce.

It was decided that a LEAN MANAGEMENT approach would be adopted because of the concepts that underpin the philosophy: continuous improvement, involvement of the entire workforce and the streamlining of production processes.

The application of the Lean methodology proved to be the perfect compromise between the goals of the management and the importance - as expressed by the divisions - of not excessively interfering with the production process.

The tool identified for the Lean project was the 5S, through which small and widespread changes were made that involved all staff, improving the work environment and everyday working relationships.

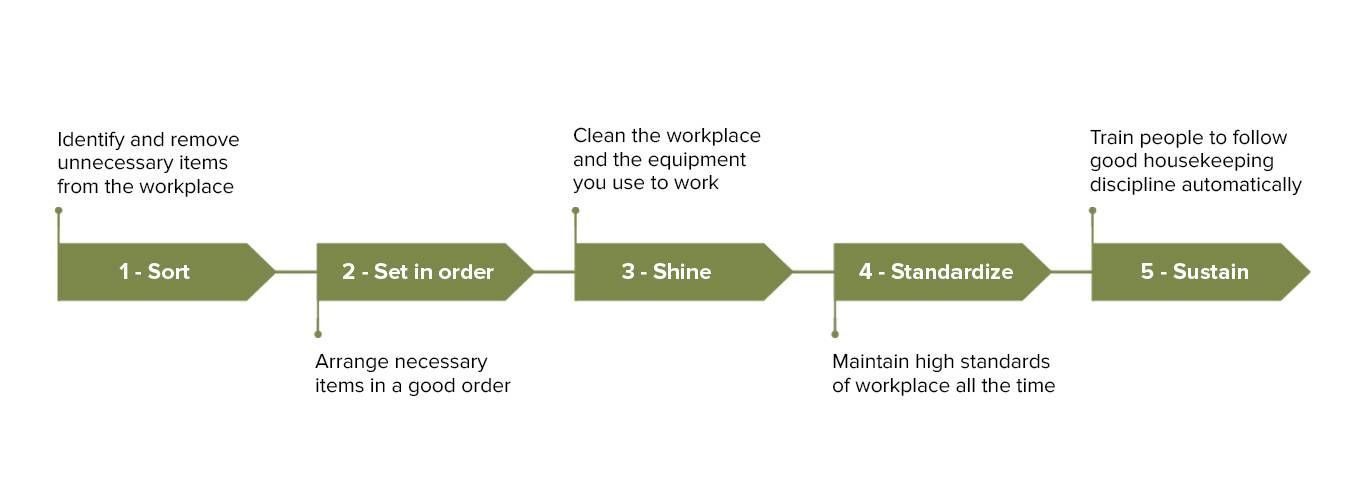

The project was therefore structured following the 5 typical steps of the 5S model:

1) Sort - Identify and remove unnecessary items from the workplace

2) Set in order - Arrange necessary items in a good order

3) Shine - Clean the workplace and the equipment you use to work

4) Standardise - Maintain high standards of workplace all the time

5) Sustain - Train people to follow good housekeeping discipline automatically

Each of the 5 meetings examined one of the “S’s” and its implementation, subsequently analysing the results.

The training activity, carried out in two work areas (assembly and delivery) at the same time, involved division managers and workers.

Conclusion

The application of the Lean methodology in the company proved to be the optimum solution for satisfying the needs outlined by the business.

The power of Lean lies in the same bases on which the methodology is founded: the concept of Kaizen. In Japanese this means the continuous improvement of operating practices, intended here in the broader sense as an improvement that involves everyone, not just processes but also personnel and therefore workspaces.